|

|

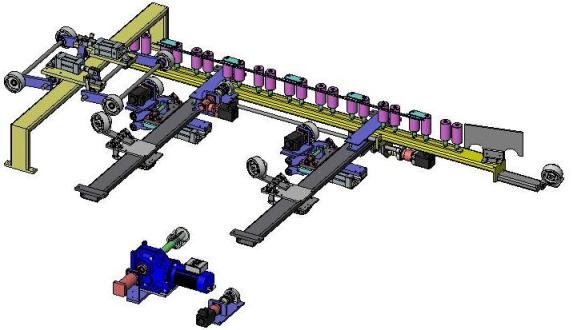

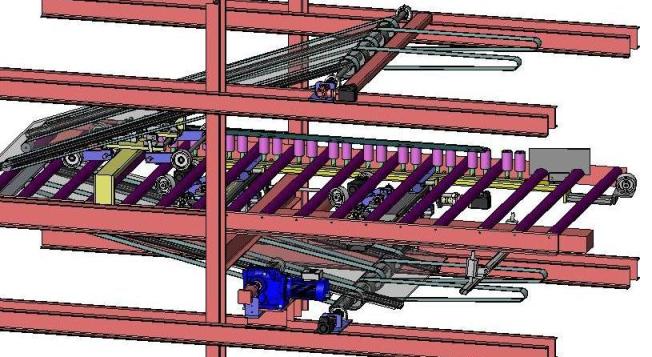

Melamine Lay-Up Alignment System

Roseburg Forest Products, INC

TriMike Creations developed a Melamine Lay-Up Alignment System for Roseburg Forest Products, a company operating in the wood products industry of Oregon. The previous alignment system was original equipment installed when the line was built. The customer’s requirements were exceeding the system’s abilities. There were constant issues with the drive and alignment system that they were unable to overcome. TMC’s challenge was to retrofit within the existing machinery an alignment system that is both accurate and flexible.

The alignment system started with a closed-loop servo drive subsystem, resulting in a significant increase in independent control of each conveyor as compared to the original chain drive system. Melamine-to-Board lineal alignment could then be accomplished on the independent conveyors through a laser-position feedback subsystem into the servo-control subsystem. Lateral alignment was achieved by utilizing a pair of servo controlled crowder rolls (right) and servo controlled “floating” guide fence, which were installed into the roll case. Board Placement was then secured through a pair of positive board clamp systems.

Testimonials

- Roy Ballard, Roseburg Forest Products – “TriMike was very responsive and developed a high quality system. They incorporated many concepts that we had not even thought about.”

- Maintenance – “It is rare that you see this quality and craftsmanship.”

Before and After Pictures:

|

|

|

Vacuum Conveyor Drive |

Main Motor Drive |

Rollcase Board Clamp |

|

|

|